304 Stainless Steel Properties – Physical and Mechanical Properties

The properties of 304 stainless steel including chemical properties, physical characteristics, thermal properties and mechanical properties, etc. The density of stainless steel 304 is 7.93 g/cm3 (0.286 lb/in3), melting point is 1400-1450 °C (2550-2650 °F), thermal conductivity is 16.2 W/m·K at 100 °C (9.4 Btu/ft·h·°F at 212 °F), yield strength is 205 MPa (30 ksi), tensile strength is 515 MPa (75 ksi), modulus of elasticity (elastic modulus) is 193 GPa (28 x 106 psi), Brinell hardness is 201 HB.

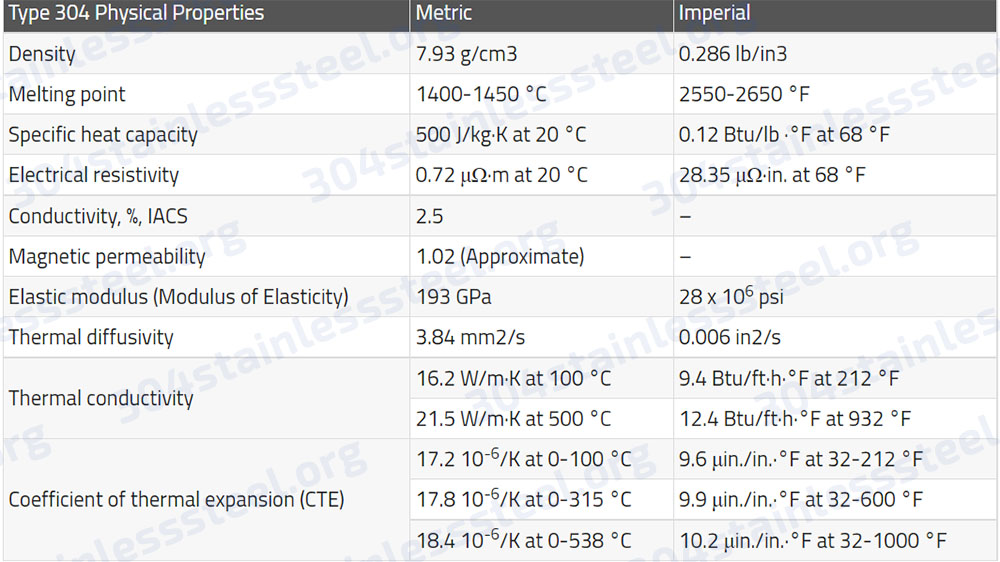

Physical Properties

304 stainless steel physical properties are listed in the table below such as density, melting point, specific heat, electrical resistivity, elastic modulus (modulus of elasticity), thermal conductivity, and coefficient of thermal expansion (CTE), etc.

Notes:

- 10-6·K-1 = 10-6/K

- 1 Ω·mm²/m = 1 μΩ·m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1 kN/mm2

- 1 MPa = 1 N/mm2

| Type 304 Physical Properties | Metric | Imperial |

| Density | 7.93 g/cm3 | 0.286 lb/in3 |

| Melting point | 1400-1450 °C | 2550-2650 °F |

| Specific heat capacity | 500 J/kg·K at 20 °C | 0.12 Btu/lb ·°F at 68 °F |

| Electrical resistivity | 0.72 μΩ·m at 20 °C | 28.35 μΩ·in. at 68 °F |

| Conductivity, %, IACS | 2.5 | – |

| Magnetic permeability | 1.02 (Approximate) | – |

| Elastic modulus (Modulus of Elasticity) | 193 GPa | 28 x 106 psi |

| Thermal diffusivity | 3.84 mm2/s | 0.006 in2/s |

| Thermal conductivity | 16.2 W/m·K at 100 °C | 9.4 Btu/ft·h·°F at 212 °F |

| 21.5 W/m·K at 500 °C | 12.4 Btu/ft·h·°F at 932 °F | |

| Coefficient of thermal expansion (CTE) | 17.2 10-6/K at 0-100 °C | 9.6 μin./in.·°F at 32-212 °F |

| 17.8 10-6/K at 0-315 °C | 9.9 μin./in.·°F at 32-600 °F | |

| 18.4 10-6/K at 0-538 °C | 10.2 μin./in.·°F at 32-1000 °F |

304 Stainless Steel Mechanical Properties

304 stainless steel mechanical properties are given in the datasheet below including tensile strength, yield strength, elongation, reduction in area, Brinell and Rockwell hardness, etc.

| ASTM A276 Type 304 Stainless Steel Mechanical Properties | ||||||

| ASTM | AISI (UNS) | Tensile Strength, Mpa (ksi), ≥ | 0.2% Yield Strength, Mpa (ksi), ≥ | Elongation in 2 in. (50 mm), %, ≥ | Reduction of Area, %, ≥ | Conditions |

| ASTM A276/A276M | 304 (UNS S30400), 304LN (UNS S30453) |

515 (75) | 205 (30) | 40 | 50 | Annealed, Hot finished |

| 620 (90) | 310 (45) | 30 | 40 | Annealed, Cold finished, Dia ≤ 1/2 in (12.7mm) | ||

| 515 (75) | 205 (30) | 30 | 40 | Annealed, Cold finished, Dia > 1/2 in (12.7mm) | ||

| ASTM A240 Type 304 Steel Mechanical Properties | ||||||

| ASTM | AISI (UNS) | Tensile Strength, Mpa (ksi), ≥ | 0.2% Yield Strength, Mpa (ksi), ≥ | Elongation in 2 in. (50 mm), %, ≥ | Brinell Hardness, HB, ≤ | Rockwell Hardness, HRB, ≤ |

| ASTM A240/A240M | 304 (UNS S30400) | 515 (75) | 205 (30) | 40 | 201 | 92 |

| ASTM A666 Type 304 Mechanical Properties | |||||||

| ASTM Standard | AISI Type (UNS) | Conditions | Tensile Strength, MPa (ksi), ≥ | 0.2% Yield Strength, MPa (ksi), ≥ | Elongation in 50 mm (2 in.), %, ≥ | Brinell Hardness (HB), ≤ | Rockwell Hardness (HRB), ≤ |

| ASTM A666 | 304 (UNS S30400) | Annealed | 517 (75) | 205 (30) | 40 | 201 | 92 |

| 1/2 Hard (Half Hard) | 1035 (150) | 760 (110) | 6 (<0.015 in); 7 (≥ 0.015 in) |

||||

| 1/4 (Quarter-hard) Hard | 862 (125) | 517 (75) | 10 (≤ 0.03 in); 12 (> 0.03 in) |

||||

| 1/8 Hard | 690 (100) | 380 (55) | 35 | ||||

| SS 304 plate, strip, sheet | 1/16 Hard | 550 (80) | 310 (45) | 40 | |||

| 304 flat bar | 620 (90) | 310 (45) | 40 (>0.030 in) | ||||

| ASTM A313 Type 304 Stainless Steel Spring Wire Tensile Strength Requirements | ||||

| Diameter (d), in. | Diameter (d), mm | Bend Test, Minimum Number of Bends | ksi | MPa |

| ≤0.009 | ≤0.23 | – | 325-355 | 2240-2450 |

| 0.009<d≤0.010 | 0.23<d≤0.25 | – | 320-350 | 2205-2415 |

| 0.010<d≤0.011 | 0.25<d≤0.28 | – | 318-348 | 2190-2400 |

| 0.011<d≤0.012 | 0.28<d≤0.30 | – | 316-346 | 2180-2385 |

| 0.012<d≤0.013 | 0.30<d≤0.33 | – | 314-344 | 2165-2370 |

| 0.013<d≤0.014 | 0.33<d≤0.36 | – | 312-342 | 2150-2360 |

| 0.014<d≤0.015 | 0.36<d≤0.38 | – | 310-340 | 2135-2345 |

| 0.015<d≤0.016 | 0.38<d≤0.41 | – | 308-338 | 2125-2330 |

| 0.016<d≤0.017 | 0.41<d≤0.43 | – | 306-336 | 2110-2315 |

| 0.017<d≤0.018 | 0.43<d≤0.46 | – | 304-334 | 2095-2300 |

| 0.018<d≤0.020 | 0.46<d≤0.51 | – | 300-330 | 2070-2275 |

| 0.020<d≤0.022 | 0.51<d≤0.56 | – | 296-326 | 2040-2250 |

| 0.022<d≤0.024 | 0.56<d≤0.61 | – | 292-322 | 2015-2220 |

| 0.024<d≤0.026 | 0.61<d≤0.66 | – | 291-320 | 2005-2205 |

| 0.026<d≤0.028 | 0.66<d≤0.71 | 8 | 289-318 | 1995-2190 |

| 0.028<d≤0.031 | 0.71<d≤0.79 | 8 | 285-315 | 1965-2170 |

| 0.031<d≤0.034 | 0.79<d≤0.86 | 8 | 282-310 | 1945-2135 |

| 0.034<d≤0.037 | 0.86<d≤0.94 | 8 | 280-308 | 1930-2125 |

| 0.037<d≤0.041 | 0.94<d≤1.04 | 8 | 275-304 | 1895-2095 |

| 0.041<d≤0.045 | 1.04<d≤1.14 | 8 | 272-300 | 1875-2070 |

| 0.045<d≤0.050 | 1.14<d≤1.27 | 8 | 267-295 | 1840-2035 |

| 0.050<d≤0.054 | 1.27<d≤1.37 | 8 | 265-293 | 1825-2020 |

| 0.054<d≤0.058 | 1.37<d≤1.47 | 7 | 261-289 | 1800-1990 |

| 0.058<d≤0.063 | 1.47<d≤1.60 | 7 | 258-285 | 1780-1965 |

| 0.063<d≤0.070 | 1.60<d≤1.78 | 7 | 252-281 | 1735-1935 |

| 0.070<d≤0.075 | 1.78<d≤1.90 | 7 | 250-278 | 1725-1915 |

| 0.075<d≤0.080 | 1.90<d≤2.03 | 7 | 246-275 | 1695-1895 |

| 0.080<d≤0.087 | 2.03<d≤2.21 | 7 | 242-271 | 1670-1870 |

| 0.087<d≤0.095 | 2.21<d≤2.41 | 7 | 238-268 | 1640-1850 |

| 0.095<d≤0.105 | 2.41<d≤2.67 | 5 | 232-262 | 1600-1805 |

| 0.105<d≤0.115 | 2.67<d≤2.92 | 5 | 227-257 | 1565-1770 |

| 0.115<d≤0.125 | 2.92<d≤3.17 | 5 | 222-253 | 1530-1745 |

| 0.125<d≤0.135 | 3.17<d≤3.43 | 3 | 217-248 | 1495-1710 |

| 0.135<d≤0.148 | 3.43<d≤3.76 | 3 | 210-241 | 1450-1660 |

| 0.148<d≤0.162 | 3.76<d≤4.11 | 3 | 205-235 | 1415-1620 |

| 0.162<d≤0.177 | 4.11<d≤4.50 | 3 | 198-228 | 1365-1570 |

| 0.177<d≤0.192 | 4.50<d≤4.88 | 1 | 194-225 | 1335-1550 |

| 0.192<d≤0.207 | 4.88<d≤5.26 | 1 | 188-220 | 1295-1515 |

| 0.207<d≤0.225 | 5.26<d≤5.72 | 1 | 182-214 | 1255-1475 |

| 0.225<d≤0.250 | 5.72<d≤6.35 | 1 | 175-205 | 1205-1415 |

| 0.250<d≤0.278 | 6.35<d≤7.06 | 1 | 168-198 | 1160-1365 |

| 0.278<d≤0.306 | 7.06<d≤7.77 | 1 | 161-192 | 1110-1325 |

| 0.306<d≤0.331 | 7.77<d≤8.41 | 1 | 155186 | 1070-1280 |

| 0.331<d≤0.362 | 8.41<d≤9.19 | 1 | 150-180 | 1035-1240 |

| 0.362<d≤0.394 | 9.19<d≤10.00 | 1 | 145-175 | 1000-1205 |

| 0.394<d≤0.438 | 10.00<d≤11.12 | 1 | 140-170 | 965-1170 |

| 0.438<d≤0.500 | 11.12<d≤12.70 | 1 | 135-165 | 930-1140 |

| >0.500 | >12.70 | – | 130-160 | 895-1105 |

| When wire is specified in straightened and cut lengths, the minimum tensile strength shall be 90 % of the values listed in the table. | ||||

| ASTM A473 Type 304 Mechanical Properties | |||||||

| ASTM | AISI (UNS) | Tensile Strength, Mpa (ksi), ≥ | 0.2% Yield Strength, Mpa (ksi), ≥ | Elongation in 2 in. (50 mm), %, ≥ | Reduction of Area, %, ≥ | Sections | Conditions |

| ASTM A473/A473M | 304 (UNS S30400) | 515 (75) | 205 (30) | 40 | 50 | ≤ 5 in. (127 mm) | Annealed |

| 485 (70) | > 5 in. (127 mm) | Annealed | |||||

| ASTM A479 Type 304 Mechanical Properties | ||||||

| ASTM | AISI (UNS) | Tensile Strength, Mpa (ksi), ≥ | 0.2% Yield Strength, Mpa (ksi), ≥ | Elongation in 2 in. (50 mm), %, ≥ | Reduction of Area, %, ≥ | Conditions |

| ASTM A479/A479M | 304, 304H, 304LN | 515 (75) | 205 (30) | 30 | 40 | Annealed |

| ASTM A580 Type 304 Mechanical Properties | ||||||

| ASTM | AISI (UNS) | Tensile Strength, Mpa (ksi), ≥ | 0.2% Yield Strength, Mpa (ksi), ≥ | Elongation in 2 in. (50 mm), %, ≥ | Reduction of Area, %, ≥ | Conditions |

| ASTM A580/A580M | SS 304 (UNS S30400) | 620 (90) | 310 (45) | 30 | 40 | Annealed, cold finished |

| 515 (75) | 205 (30) | 35 | 50 | Annealed | ||

Comments are closed.